Unlock the Secrets of TPU Filament: Discover Its Amazing Benefits and Versatile Applications in 3D Printing!

In the ever-evolving world of 3D printing, 3d printing with tpu filament has emerged as a game-changer, captivating the interest of hobbyists and professionals alike. Thermoplastic Polyurethane (TPU) is a flexible, rubber-like material that boasts unique properties, making it a preferred choice for a wide range of applications. As the demand for innovative and adaptable materials grows, TPU stands out for its remarkable combination of flexibility, durability, and resilience. Whether you're creating intricate designs or functional parts, understanding TPU filament's characteristics is essential for harnessing its full potential in your 3D printing projects.

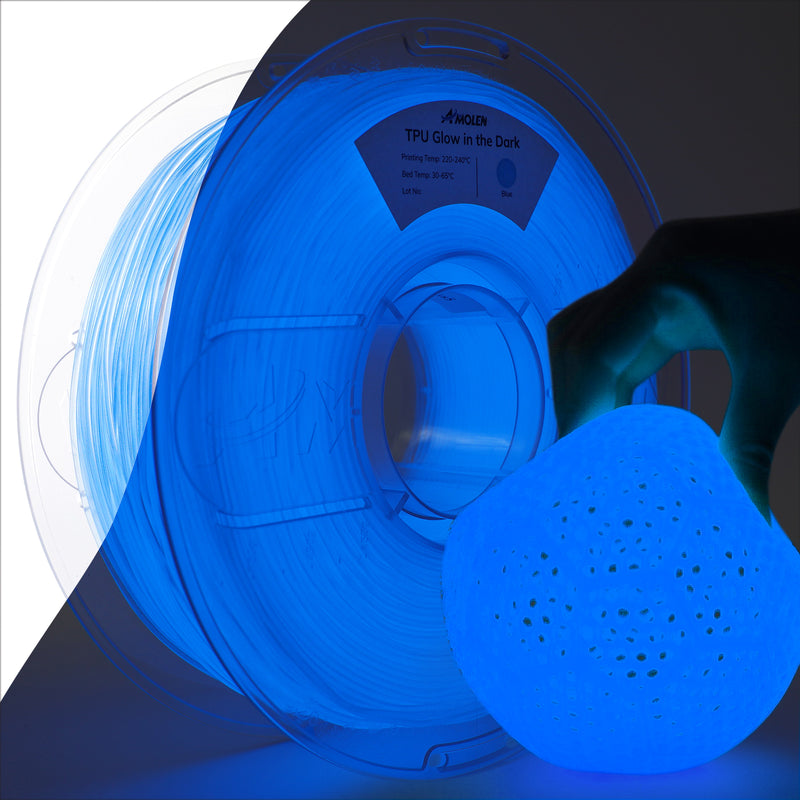

Understanding TPU Filament

TPU filament is a type of thermoplastic elastomer that combines the properties of rubber and plastic. This unique material is composed of soft and hard segments, resulting in a filament that is both flexible and robust. Unlike traditional filaments like PLA or ABS, TPU is highly elastic, allowing it to stretch without breaking, which makes it ideal for applications requiring flexibility. Its resistance to abrasion and wear ensures that printed parts maintain their integrity over time, even under significant stress. This versatility in properties makes TPU suitable for a variety of 3D printing projects, from prototypes to end-use products.

Benefits of Using TPU Filament in 3D Printing

The advantages of TPU filament in 3D printing are numerous. One of the most notable benefits is its extraordinary flexibility, allowing printed objects to bend and compress without losing their shape. This characteristic is particularly advantageous for creating items that must endure repeated stress, such as phone cases and wearables. Additionally, TPU offers excellent shock absorption, making it an ideal choice for protective components. Furthermore, TPU filament is relatively easy to print, provided the right settings and techniques are employed. Its eco-friendliness, being both recyclable and produced from renewable resources, adds to its appeal, making it an attractive option for environmentally conscious creators.

Versatile Applications of TPU Filament

TPU filament has found applications across various industries, showcasing its remarkable versatility. In the automotive sector, it is used for creating custom gaskets, seals, and flexible components that require durability and flexibility. Healthcare professionals utilize TPU for producing prosthetics and orthopedic devices that need to conform to dynamic body movements. Fashion designers, too, have embraced TPU to create unique accessories and footwear that not only look good but are also functional. Additionally, consumer products such as smartphone cases, sporting goods, and toys benefit from TPU's durability and flexibility, making it a go-to material for innovative product design.

Printing Tips and Considerations for TPU Filament

Printing with TPU filament does require some specific considerations to ensure the best results. First, it's crucial to adjust your printer settings, such as using a slower print speed and a lower temperature, which can help prevent stringing and ensure better layer adhesion. Bed adhesion is also critical; using a heated bed or applying a suitable adhesive can help prevent warping. Additionally, consider employing a direct drive extruder, as it provides better control when pushing the flexible filament through the nozzle. Lastly, post-processing techniques like trimming or sanding may be necessary to achieve the desired finish. By addressing these factors, you can overcome common challenges and produce high-quality prints with TPU.

Unlocking the Potential of TPU Filament

In summary, TPU filament presents a host of benefits that make it a compelling choice for 3D printing enthusiasts and professionals alike. With its flexibility, durability, and wide-ranging applications, TPU opens the door to innovative design possibilities across multiple industries. Whether you're looking to create functional prototypes or eye-catching consumer products, TPU can help you achieve your goals. We encourage you to experiment with TPU in your own projects—its potential for creativity and innovation in the 3D printing landscape is truly remarkable.