Unlock the Secrets to Perfect TPU Filament: Your Ultimate Guide to Smart Buying and Flawless Printing!

Thermoplastic Polyurethane (TPU) filament is gaining popularity among 3D printing enthusiasts and professionals alike. Its unique properties make it an ideal choice for creating flexible, durable, and intricate designs. However, achieving the best results with TPU requires more than just the right material; understanding the optimal printing settings is crucial, particularly the head temperature. Selecting the right filament and fine-tuning your printer's settings can significantly affect the quality of your prints, leading to more successful projects and less wasted time and materials.

Understanding TPU Filament

TPU filament is a type of flexible filament made from thermoplastic elastomers, known for its rubber-like properties. This versatile material offers excellent flexibility and durability, making it perfect for a variety of applications, from functional parts to artistic creations. One of the key attributes of TPU is its ability to withstand wear and tear, making it ideal for items that require a high degree of flexibility, such as phone cases, gaskets, and even footwear. With its impressive tensile strength and resistance to abrasion, TPU allows for the creation of objects that maintain their shape under stress, which is why it has become a favorite among 3D printing enthusiasts looking to push the boundaries of design.

Key Factors to Consider When Buying TPU Filament

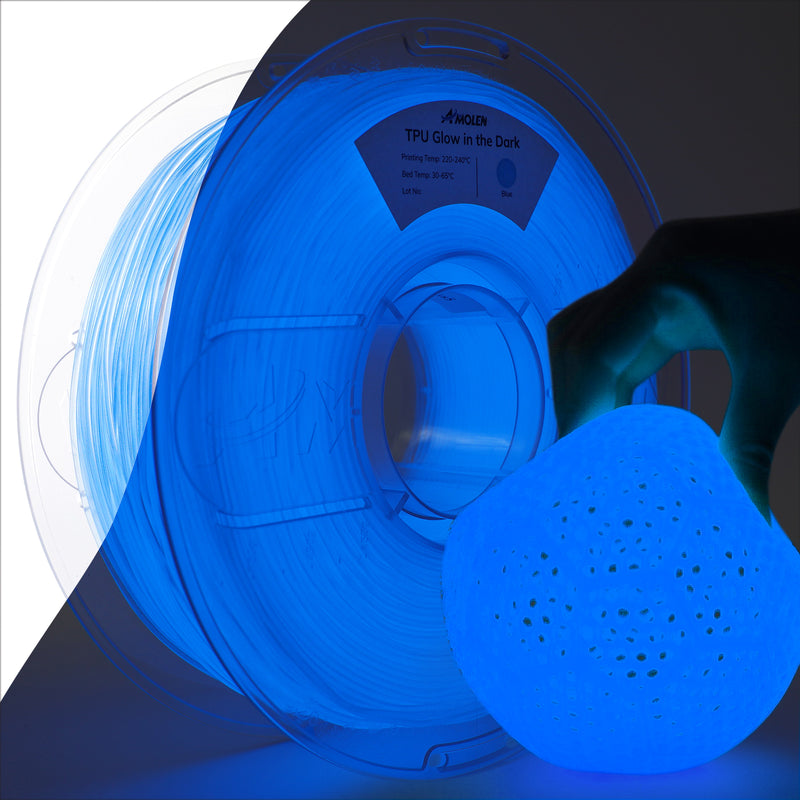

When purchasing TPU filament, several key factors should be taken into account to ensure you get the best quality for your printing needs. Firstly, the filament diameter is crucial; most printers use 1.75mm or 2.85mm filament, and compatibility with your printer's specifications is a must. Additionally, color options can significantly affect the final appearance of your prints, so choose a color that fits your project requirements. Packaging also matters—look for vacuum-sealed packages to minimize moisture absorption, which can negatively impact print quality. These elements not only influence the aesthetic but also play a vital role in print consistency and performance, making informed buying choices essential for optimal results.

Optimal Printer Settings for TPU Filament

Getting the head temperature right is one of the most critical aspects of successfully printing with TPU filament. Generally, the recommended head temperature for TPU ranges from 220°C to 250°C. However, this can vary depending on the specific type of TPU and the 3D printer you are using. A lower temperature may lead to under-extrusion, while a temperature that is too high can cause the filament to become overly soft, leading to stringing or poor layer adhesion. It’s essential to conduct tests to find the sweet spot for your specific setup. I learned this the hard way when a friend of mine printed a complex design and ended up with a melted mess instead of the intended flexible part. Adjusting the temperature settings made all the difference in achieving a successful print.

Other Printing Parameters

In addition to head temperature, there are several other printing parameters that can influence the outcome when using TPU filament. Bed temperature is another important setting; a heated bed can help prevent warping and improve adhesion, with a typical range being around 40°C to 60°C. Print speed also plays a role; slower speeds are generally better for TPU, as they allow for more precise extrusion. Retraction settings should be adjusted as well, with minimal retraction distance and speed recommended to avoid clogging and filament jams. Balancing these settings can significantly enhance the quality and reliability of your prints.

Common Issues and Troubleshooting Tips

Despite the advantages of TPU filament, users may encounter common issues during printing. One frequent problem is stringing, which can occur if the head temperature is too high or the print speed is too fast. To mitigate this, consider lowering the temperature or adjusting the retraction settings. Another issue is poor adhesion to the print bed, which can lead to warping. Ensuring the bed is clean and properly leveled, combined with the right temperature, can help resolve this. If you experience under-extrusion, check for clogs in the nozzle or consider increasing the temperature slightly. Regularly troubleshooting these issues is essential for maintaining print quality and achieving the best results with TPU filament.

Maximizing Your TPU Printing Experience

In summary, purchasing TPU filament and optimizing your 3D printer settings go hand in hand for achieving the best printing results. By understanding the properties of TPU, making informed buying decisions, and fine-tuning settings such as head temperature and print speed, you can enhance your printing experience. It’s essential to experiment and adjust your parameters based on the specific filament and printer you are using. With patience and practice, you’ll unlock the full potential of TPU filament, leading to successful and impressive 3D prints.