Unlock the Magic of 3D Printing: Discover the Best TPU Filament Creations You Can't Resist!

3D printing technology has revolutionized the way we think about manufacturing and design, allowing for unprecedented creativity and customization. Among the vast array of materials available for 3D printing, TPU (Thermoplastic Polyurethane) filament stands out due to its remarkable versatility and unique properties. This flexible, durable material is ideal for a wide range of applications, from functional prototypes to intricate designs. In this article, we'll explore the potential of TPU filament, showcasing inspiring creations that you can craft yourself, and providing a comprehensive guide on how to master 3D printing with this exceptional material.

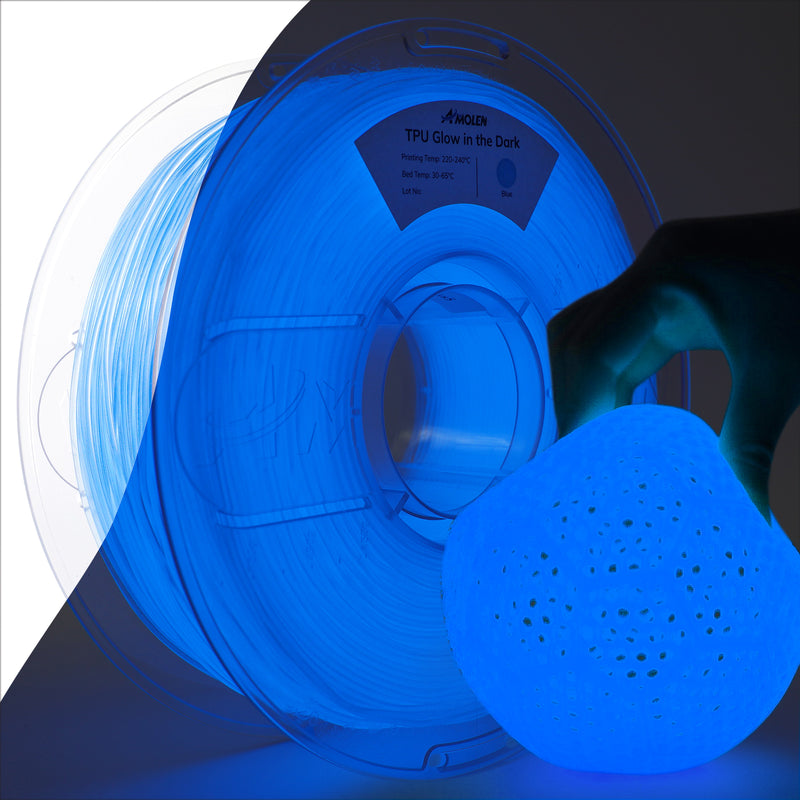

Understanding TPU Filament

TPU filament is a type of flexible filament used in 3D printing, known for its impressive elasticity and resilience. Made from thermoplastic polyurethane, TPU combines the best of both worlds: the durability of traditional plastics and the flexibility of rubber. It can stretch and compress without losing its original shape, making it an excellent choice for products that require a high degree of flexibility. Additionally, TPU is resistant to abrasion and has good chemical resistance, which enhances its usability across various industries. This makes TPU ideal for applications in automotive parts, sporting goods, and even medical devices. The growing popularity of TPU filament in the 3D printing community can be attributed to its ease of use and the stunning designs it can produce, encouraging hobbyists and professionals alike to explore its potential.

Popular TPU Filament Creations

The creative possibilities with TPU filament are virtually endless. One of the most popular applications is the creation of custom phone cases, which not only protect devices but can also be personalized to reflect individual styles. Footwear is another exciting category; 3D printed shoes or insoles made from TPU provide comfort and flexibility, revolutionizing the way we think about footwear design. Additionally, custom toys crafted from TPU highlight the material's ability to produce vibrant colors and intricate details, making them appealing to both children and collectors. Other notable creations include wearable tech, such as fitness bands that require flexibility and durability. From practical items to whimsical designs, TPU filament can bring a host of creative ideas to life.

Step-by-Step Guide to 3D Printing with TPU Filament

To successfully 3D print with TPU filament, follow these essential steps that will help you achieve the best results. First, ensure your 3D printer is compatible with flexible filaments; if it has a direct drive extruder, you are in good shape. One of the critical factors when printing with TPU is the printer settings. A slower print speed (around 20-30 mm/s) is recommended to ensure the filament flows smoothly through the extruder. Temperature settings are also vital; a hot end temperature between 220 to 250 degrees Celsius usually works best for TPU. Bed adhesion can be tricky due to the filament's flexibility; using a heated bed set to around 50-60 degrees Celsius can help, along with applying a glue stick or blue painter's tape for extra grip. After preparing your printer, it’s time to load the TPU filament. Ensure the filament is dry, as moisture can affect print quality. Watch for any signs of stringing during printing, which can occur with flexible materials. Adjusting retraction settings and ensuring the nozzle is clean can help mitigate this issue. Once printing is complete, careful post-processing can enhance the final product. This may involve trimming away any excess material or smoothing the surface with heat to improve aesthetics. By following these steps, you can confidently create stunning 3D printed items using TPU filament.

Common Challenges and Solutions

While printing with TPU filament can be rewarding, it does come with its challenges. One common issue is stringing, where fine strands of plastic are left between parts of the print. To combat this, reduce the retraction distance and speed in your printer settings. Warping can also occur, especially if the bed is not adequately heated. Make sure your bed is clean and properly leveled, and consider using an enclosure to maintain a stable temperature around the print. If you encounter adhesion issues, switching to a different surface or increasing the bed temperature may help. With these tips, you can troubleshoot and resolve common problems while printing with TPU filament.

Exploring the Creative Potential of TPU Filament

In conclusion, TPU filament opens up a world of creative potential for 3D printing enthusiasts. Its unique properties provide the flexibility and durability needed to produce a wide range of functional and artistic creations. From custom phone cases to innovative footwear, the applications of TPU are vast and varied. By mastering the techniques outlined in this article, you'll be well-equipped to explore the endless possibilities this material has to offer. So gather your materials, unleash your creativity, and start your journey into the fascinating realm of TPU filament 3D printing!